BOC Sciences specializes in the custom development and preparation of high-performance PCL-based hydrogels for applications in medical aesthetics, cosmetics, and biomedicine. Leveraging our advanced polymerization technology platform and a team of materials science experts, we offer precise molecular design of polycaprolactone (PCL), controllable tuning of hydrogel properties, and functional modifications to deliver ideal solutions with excellent biocompatibility, stability, and biodegradability. Whether for drug delivery systems, tissue engineering scaffolds, or skin repair carriers, BOC Sciences provides end-to-end services from research and development to scale-up manufacturing, empowering clients to accelerate product commercialization and drive innovation.

BOC Sciences, with its powerful R&D team and technical background, is capable of offering highly customized PCL hydrogel preparation solutions based on specific customer needs. We can precisely control the structure, properties, degradation rate, and biocompatibility of the hydrogel.

We use industry-leading preparation technologies, such as chemical crosslinking, physical crosslinking, solvent evaporation, and freeze-drying, among others, ensuring that the hydrogels have excellent mechanical properties, biocompatibility, and stability.

BOC Sciences integrates technologies from fields such as chemistry, materials science, and bioengineering to offer comprehensive technical support. From formula design to process optimization, we provide one-stop solutions to meet customer needs.

We have a complete quality control system and advanced analytical equipment to ensure that every batch of PCL hydrogel meets industry standards. Our quality control process spans across R&D, production, and delivery stages.

With flexible capabilities ranging from small-scale trial production to large-scale manufacturing, we can offer precise solutions based on customer requirements and production scale. Whether it's initial small-batch sample R&D or large-scale production, we provide high-quality PCL hydrogels efficiently and consistently.

BOC Sciences is committed to the continuous development of new materials and technologies, driving the innovative progress of PCL hydrogels. Through ongoing technological accumulation and cross-industry collaborations, we continually optimize and improve the properties of hydrogels.

BOC Sciences provides comprehensive, customized formula development and optimization services based on customer requirements. Whether it is for skin repair in medical aesthetics, moisturizing effects in cosmetics, or drug delivery systems in biomedical applications, we offer precise formula design to meet practical customer needs. With strong laboratory facilities and R&D teams, we can conduct extensive testing and validation during the early stages of formulation to ensure the efficacy and feasibility of the final product.

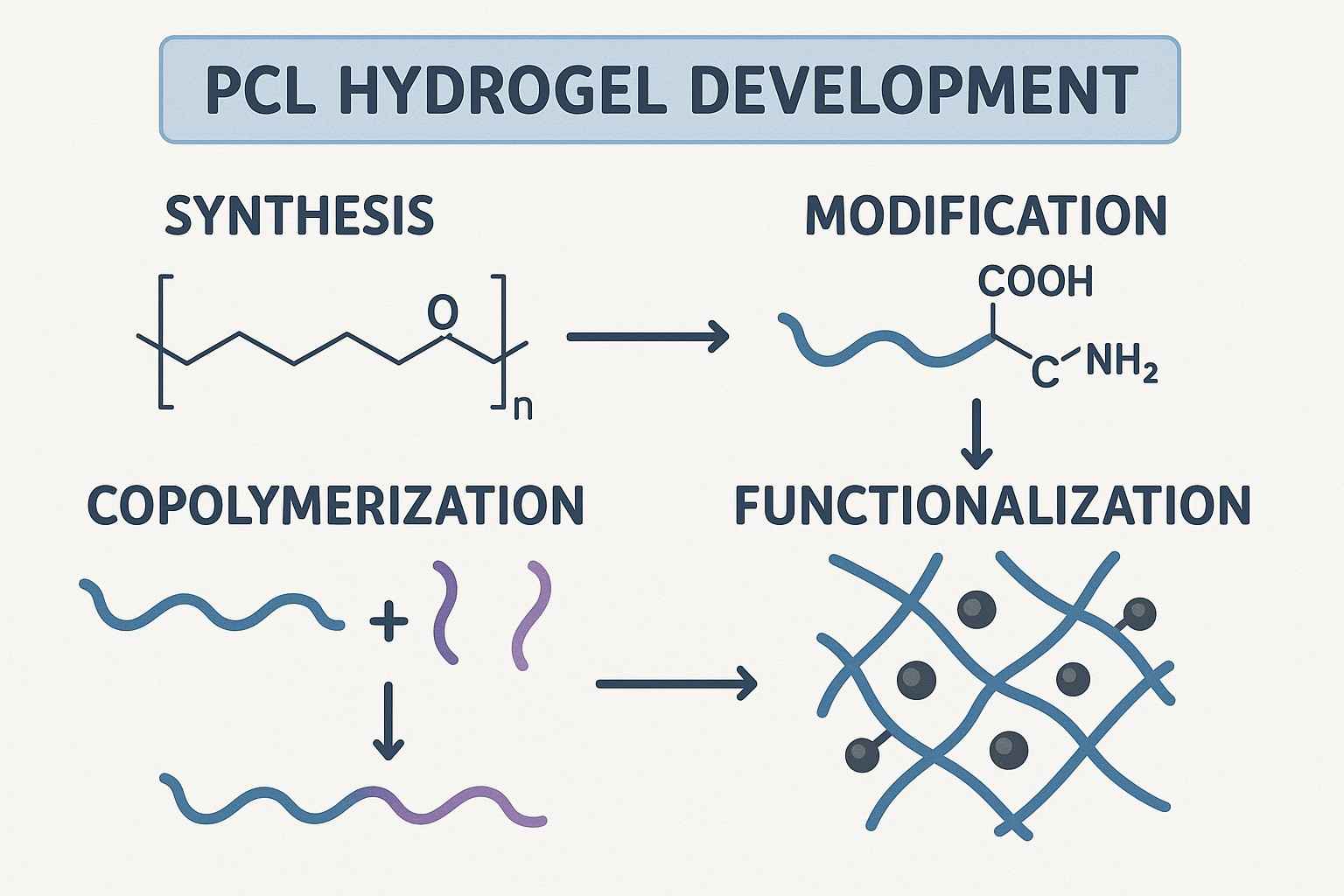

By precisely controlling polymerization conditions and adjusting factors such as PCL molecular weight and crosslinking density, BOC Sciences can produce hydrogels with ideal mechanical strength, water absorption, and biodegradability. Customers can choose different synthesis and modification methods based on specific application needs, such as drug delivery and tissue engineering.

To improve the performance of PCL-based hydrogels, BOC Sciences offers compositing services with other hydrophilic polymers (e.g., PVA, gelatin, carboxymethyl cellulose). Through compositing and copolymerization, we optimize the hydrogel's water absorption, mechanical strength, and degradation rate, making it more suitable for drug delivery, wound healing, and tissue engineering.

BOC Sciences offers surface modification services for PCL-based hydrogels by introducing biomolecules, antibodies, peptides, etc., to functionalize the hydrogels. Surface modification can enhance the biocompatibility of hydrogels, promote cell attachment, or increase drug-loading capacity, thus improving the performance of hydrogels in in vivo applications.

For personalized customer needs, BOC Sciences provides custom development services for PCL-based hydrogels, ranging from small-scale production during the laboratory phase to pilot-scale production. Customers can rely on BOC Sciences' technical expertise and production capabilities for a smooth transition from R&D to the market.

The preparation process for PCL hydrogels is highly adjustable and can be optimized and selected based on specific application requirements and target properties. Different preparation methods affect key characteristics such as structure, mechanical properties, degradation rate, and biocompatibility. Therefore, when providing customized PCL hydrogel preparation services, BOC Sciences offers a variety of preparation process options, ensuring that the hydrogels meet the specific requirements based on customer application needs, production scale, and budget.

The chemical crosslinking method uses crosslinking agents (such as isophorone diisocyanate (IPDI), epoxides, etc.) to link PCL molecular chains into a three-dimensional crosslinked network structure. This method significantly enhances the mechanical performance, stability, and strength of the hydrogel, making it suitable for long-term implantation applications in medical aesthetics and biomedical fields.

The physical crosslinking method relies on physical interactions (such as freeze-drying, thermoplastic molding, etc.) to form a crosslinked structure. This method is easy to operate and is suitable for applications that require rapid molding and high biocompatibility, such as cosmetics and wound dressings.

The freeze-drying method freezes PCL solution containing water under low temperatures and removes the water to form a hydrogel with high porosity and good structure. This process is particularly suitable for PCL hydrogels that require high porosity, large surface area, and low density, with wide applications in cell carriers and tissue engineering.

Adding other polymers or nanomaterials (e.g., polyethylene glycol, chitosan, nanoparticles) to PCL hydrogels can significantly improve their performance. For example, PCL/polyethylene glycol composite hydrogels provide better mechanical strength and biodegradability, while PCL/nanoparticle composites enable more precise drug release control.

BOC Sciences possesses advanced GMP-certified manufacturing facilities to provide high-quality, large-scale production services for PCL hydrogels. Our production workshops strictly follow GMP standards and are equipped with the latest equipment and monitoring systems to ensure quality control and contamination-free production processes. From raw material procurement and environmental control during production to final product inspection, we adhere to processes that comply with industry regulations and international standards. Our GMP manufacturing capabilities support large-volume production while ensuring consistency, stability, and high quality, meeting the strict requirements for hydrogels in medical aesthetics, cosmetics, and biomedical fields. BOC Sciences' GMP-certified production facilities enable customers to confidently rely on our products, ensuring reliable quality assurance for commercial-scale manufacturing.

BOC Sciences offers comprehensive PCL hydrogel quality testing services aimed at ensuring the performance and quality of each batch of products meets the highest standards. Using advanced analytical techniques and equipment, we conduct thorough performance characterization and quality assessment across multiple aspects, including physical, chemical, and biological properties. Our quality control team will provide detailed analysis for each specific parameter based on the customer's requirements, ensuring the superiority and stability of PCL hydrogel in applications. Whether during the R&D phase or large-scale production, we offer reliable data support to help customers ensure the final product's effectiveness and market competitiveness. Below are the analysis items and testing instruments we provide:

PCL hydrogel is widely applied in fields such as biomedicine, cosmetics, and medical aesthetics due to its unique properties. As a material with good biocompatibility, adjustable degradation rates, and excellent mechanical properties, PCL hydrogel plays a vital role across various industries. With its adjustable degradability and diverse application forms, PCL hydrogel is becoming a core material in the development of a range of products, driving innovation in the biopharmaceutical and beauty industries.

PCL (Polycaprolactone) itself is not a hydrogel, but PCL-based hydrogels can be prepared. By combining PCL with crosslinkers or other polymer materials such as PEG, PCL can form a hydrogel with water absorption and high hydration properties. PCL-based hydrogels typically exhibit good biodegradability, biocompatibility, and controllable release properties, making them widely applied in drug release, wound healing, and other biomedical fields.

PCL is commonly used in skin repair, particularly in wound healing and burn treatment. Its biocompatibility and degradability make it valuable in skin repair materials, promoting cell growth, accelerating the healing process, and reducing scar formation.

Polycaprolactone (PCL) is considered safe for the human body. It has been widely used in medical implants, drug delivery systems, and biomedical materials. Due to its good biodegradability and low toxicity, PCL is deemed suitable for human use, though it should still be evaluated based on its specific application.