BOC Sciences delivers polycaprolactone (PCL) microsphere modification services that address the specific requirements of the medical aesthetics industry together with cosmetic and biomedical applications. Our PCL microspheres come in particle sizes between 1-100 μm with custom modifications for medical-grade PMMA microspheres as well as cosmetic-grade and industrial-grade PMMA microspheres. We deliver customized solutions for drug delivery applications, skin repair procedures, and biomedical research needs to fulfill our clients' requirements as we improve microspheres' biocompatibility, stability, and functionality.

During the modification process of PCL microspheres, uneven surface coatings or unstable composite materials may affect the morphology and performance of the microspheres. BOC Sciences offers high-precision microsphere surface modification technology, ensuring morphological and structural stability during the modification process.

PCL microspheres may have uneven drug loading, affecting the precise control of drug release. By optimizing the preparation process and modifying materials, we ensure uniform drug loading and controlled release performance.

Materials introduced during the modification process may affect the biocompatibility and immune response of the microspheres. BOC Sciences focuses on using biocompatible polymer materials to ensure the safety and good biocompatibility of the microspheres.

The degradation rate of PCL is difficult to control precisely, which may lead to uneven drug release. Through copolymerization and composite material modification techniques, we precisely adjust the degradation rate to meet the needs of different applications.

During large-scale production, the quality and performance of microspheres may vary between batches. BOC Sciences has large-scale, repeatable production processes to ensure the stability and consistency of each batch of microspheres.

The modification of PCL microspheres typically requires complex processes, which increases production costs. BOC Sciences has optimized the process flow to reduce production costs while maintaining high-quality microsphere performance.

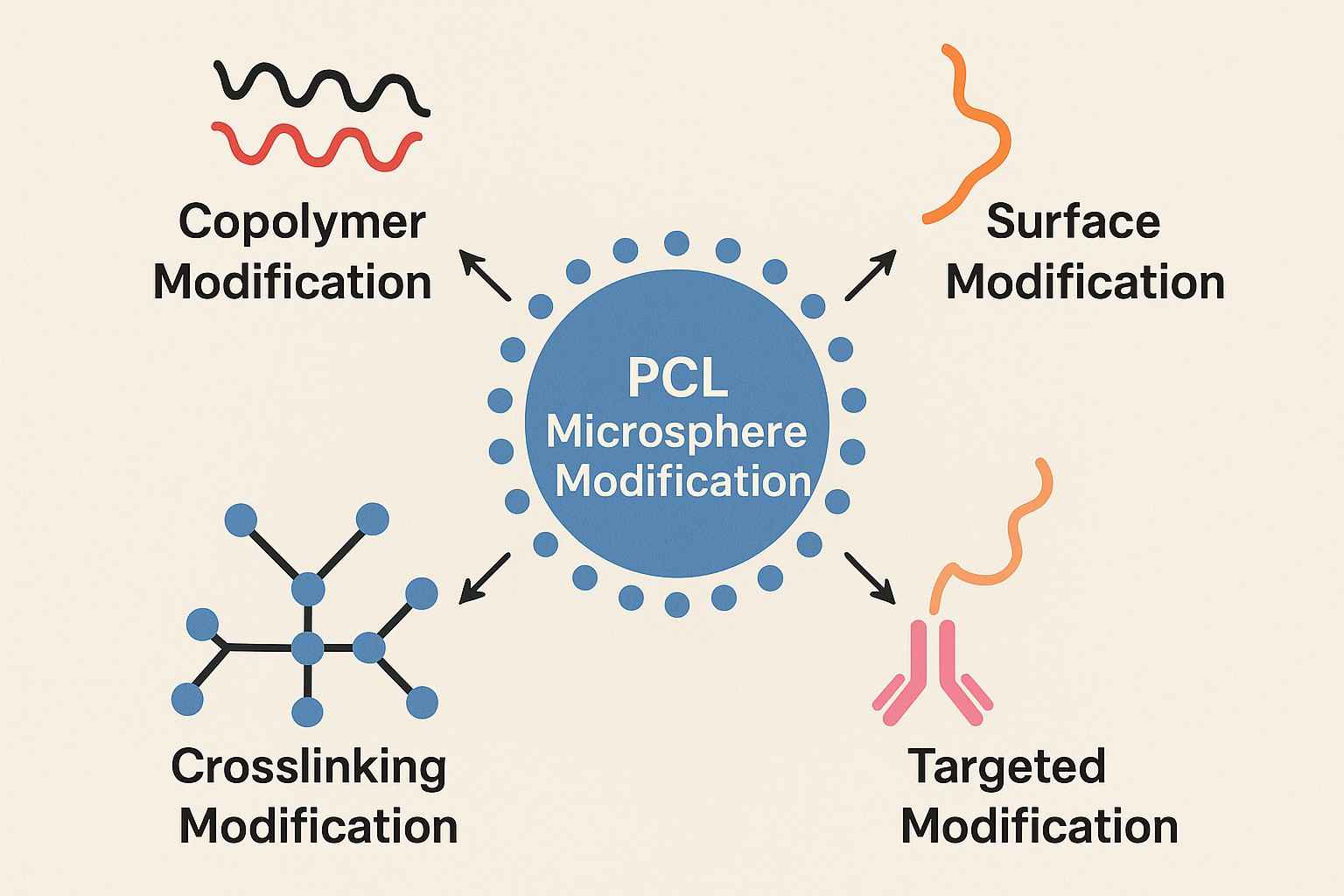

BOC Sciences offers a series of specialized PCL microsphere modification services designed to meet the diverse needs of industries such as medical aesthetics, cosmetics, and biomedical fields. Through advanced technological methods, we can customize the performance of PCL microspheres based on client requirements to improve their efficacy in drug delivery, skin repair, and other applications. Our modification technologies include blending, nano-sizing, surface modification, targeted modification, copolymer modification, crosslinking modification, pH-responsive modification, and temperature-responsive modification, ensuring the stability, functionality, and biocompatibility of microspheres. With years of technical accumulation and industry experience, BOC Sciences provides clients with efficient, safe, and industry-standard PCL microsphere solutions.

Using advanced blending technology, BOC Sciences blends PCL with other polymer materials (such as PLGA, PEG, PVA, etc.), adjusting the mechanical properties, degradation rate, and drug release properties of PCL microspheres.

Through nano-sizing technology, BOC Sciences can precisely control the particle size of PCL microspheres within the nanoscale range, enhancing their drug loading capacity and cellular absorption, particularly suitable for targeted drug delivery and skin penetration.

By introducing functional groups (such as amino groups, carboxyl groups, peptide chains, etc.) to the surface of PCL microspheres, we can improve their hydrophilicity, hydrophobicity, or biocompatibility, or endow them with specific targeting functions.

By modifying specific targeting molecules (such as antibodies, peptides, sugar molecules, etc.) onto the surface of PCL microspheres, we enable targeted delivery of drugs or active ingredients to specific cells or tissues.

Through crosslinking reactions, a three-dimensional network structure is formed between PCL molecules, enhancing the structural stability of PCL microspheres and adjusting their degradation rate. The degree of crosslinking can significantly alter the mechanical properties, degradation process, and drug release pattern of the microspheres.

Using pH-responsive modification technology, PCL microspheres can adaptively release drugs according to changes in environmental pH, particularly suitable for drug delivery in acidic or alkaline environments, such as tumor-targeted therapy.

BOC Sciences utilizes temperature-responsive modification technology to enable PCL microspheres to change their physical properties under specific temperature conditions, achieving more precise drug release control, suitable for the delivery and treatment of thermosensitive drugs.

For combination therapies, we provide multi-drug loaded microsphere preparation services, enabling PCL microspheres to load multiple drugs simultaneously, achieving synergistic therapeutic effects.

BOC Sciences has strong GMP manufacturing capabilities for PCL microspheres, ranging from small-scale laboratory production to pilot-scale and large-scale production, providing clients with comprehensive customized services. Our manufacturing processes strictly follow GMP standards, ensuring the quality and consistency of every batch of products. During small-scale production, we quickly optimize formulations and conduct preliminary production process verification according to customer needs. In the pilot-scale stage, we simulate large-scale production environments, optimizing process conditions, laying the foundation for large-scale production. In the large-scale production stage, we have advanced facilities and precise control systems to efficiently and safely produce PCL microspheres, meeting high-volume and complex requirements. Additionally, our quality management system covers the entire process, from raw material procurement to finished product inspection, ensuring that every batch undergoes rigorous validation and testing to meet customers' high standards.

BOC Sciences offers comprehensive PCL microsphere quality testing services, aimed at ensuring every batch of products meets strict quality standards and satisfies client application needs. Our quality testing services include evaluating the physical, chemical, and biological properties of microspheres to ensure their stability, efficacy, and safety in practical applications. We have advanced testing equipment and professional technical teams capable of accurately characterizing the performance of PCL microspheres, providing detailed quality assessment reports and reliable data support to our clients.

PCL microspheres, with their unique structure and physical properties, can effectively encapsulate and provide controlled release of various active ingredients, offering long-lasting and stable effects. As fields such as biomedicine, cosmetics, drug delivery, and regenerative medicine continue to develop, PCL microspheres, as a carrier material, show immense potential in precise treatments and long-term outcomes. Their applications in areas such as dermal fillers, drug delivery, tissue engineering, wound healing, and vaccine delivery have significantly advanced related technologies. Furthermore, the biodegradability of PCL microspheres offers advantages in terms of environmental impact and patient safety, reducing the burden on the environment.

Polymeric microspheres are tiny spherical particles made from polymer materials, typically in the micron size range. They have a large surface area, allowing them to load drugs, active ingredients, or other substances, and control their release rate. Polymeric microspheres are widely used in drug delivery, cosmetics, tissue engineering, diagnostic imaging, and other fields, providing sustained and controllable effects by modulating degradation characteristics.

Polycaprolactone (PCL) is a synthetic polymer material. It is synthesized through a ring-opening polymerization reaction and possesses excellent biocompatibility, degradability, and adjustable degradation rates. PCL is commonly used in drug delivery, tissue engineering, and other fields, gaining widespread attention due to its stability and controllability.

Polycaprolactone (PCL) is primarily used in skincare as a controlled-release carrier and filler. It effectively encapsulates active ingredients, such as anti-aging agents and moisturizers, gradually releasing them into the skin to extend the duration of skincare effects. Additionally, PCL microspheres can fill fine lines and wrinkles, improving the skin's appearance, enhancing firmness, and promoting skin repair and regeneration.