With strong formulation development capabilities and an advanced technology platform, BOC Sciences provides one-stop customized services for the medical aesthetics and cosmetics industries. These services range from ingredient screening, formulation optimization, and quality control to GMP manufacturing, helping global clients efficiently, compliantly, and safely transform R&D achievements into market-competitive products. Our interdisciplinary technical team integrates cutting-edge research in organic synthesis, biochemistry, materials science, and pharmaceutics to deliver personalized, high-quality formulation solutions for various topical formulations, injectable fillers, cosmetic peptides, and active ingredient delivery systems. Our clients include medical aesthetics institutions, skincare brands, biopharmaceutical companies, and premium cosmetics manufacturers. We are committed to advancing scientifically driven medical aesthetic products into clinical and commercial use.

BOC Sciences has a robust R&D team capable of tailoring functional formulations based on customer needs, optimizing stability, biocompatibility, and active ingredient release performance.

We integrate premium global raw material resources, covering peptides, proteins, polymers, and bioactive molecules, ensuring raw material quality and providing end-to-end technical services from screening to validation.

Leveraging a multidisciplinary collaboration platform across chemistry, biology, and materials science, we continuously innovate in carrier development, transdermal technologies, and controlled release systems to meet diverse clinical and application demands.

BOC Sciences excels in various dosage form designs, such as gels, injections, microspheres, liposomes, emulsions, and lyophilized preparations, catering to differentiated product development needs in medical aesthetics and premium cosmetics.

The company is equipped with internationally compliant GMP facilities capable of pilot, scale-up, and commercial production, ensuring product safety, traceability, and consistency in line with regulatory standards.

We offer end-to-end technical management services covering proof of concept, formulation screening, stability testing, and regulatory submission, helping clients advance projects efficiently and accelerate product launch timelines.

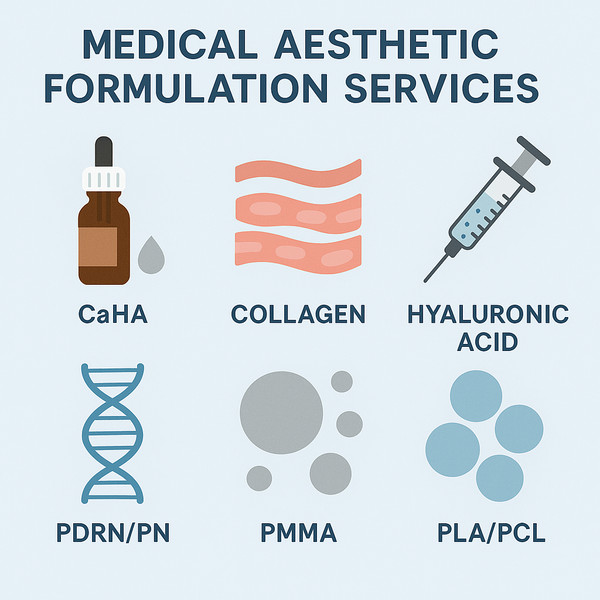

In the field of medical aesthetics and cosmetics industries, BOC Sciences provides formulation design and technical optimization services for a variety of mainstream and emerging products, covering common injectable fillers, regenerative active ingredients, functional particles, and peptide systems. Our service scope includes but is not limited to the following product categories:

We participate in the formulation optimization and stabilization of Type A and B botulinum toxins, including prevention of protein aggregation, development of lyophilized dosage forms, and incorporation of sustained-release systems.

As a particulate filler, CaHA is widely used in facial contouring due to its dual functions of volume support and collagen stimulation. BOC Sciences provides services including CaHA particle embedding systems, dispersion stability improvement, and injectable formulation process development.

Whether extracted from animal sources or produced via recombinant expression, we offer services for collagen purification, crosslinking, stabilization, and formulation, including lyophilized powders, injectables, and mask formulations for various applications.

We have mature technologies for developing high-, medium-, and low-molecular-weight HA formulations, including crosslinked HA fillers, compound HA serums, and sustained-release carrier systems, supporting product development for moisturizing, repair, and shaping applications.

BOC Sciences provides services including PDRN extraction and purification, concentration ratio optimization, and combination formulation design with other biofactors. These are widely applied in skin repair and tissue regeneration projects in medical aesthetics.

We develop sustained-release systems, penetration-enhancing combination technologies, and cold chain stability formulations for PN ingredients, used in products targeting cell regeneration, anti-aging, and antioxidation, especially in injectable aesthetics and post-surgical repair.

PMMA microspheres are commonly used in permanent fillers due to their high stability and long-term support. We assist in particle size control, surface modification, and injectable formulation development for PMMA microspheres.

BOC Sciences has extensive experience in sustained-release drug delivery systems based on PLA particles and microspheres, suitable for long-acting fillers that stimulate collagen regeneration. We also support the construction of compound systems combining PLA with HA or collagen.

We develop its applications in injectable fillers, implantable sustained-release systems, and combination drug delivery platforms, suitable for deep tissue filling, volume modification, and high-end personalized cosmetic procedures.

We offer gel development services based on agarose as a matrix, suitable for transparent injectable fillers or physical encapsulation systems, with good biocompatibility and injectability.

For exosomes derived from various sources (e.g., mesenchymal stem cells), we provide extraction and purification, active component protection, lyophilized formulation development, and skin delivery system construction to meet functional needs in anti-inflammation, anti-aging, whitening, and more.

For peptides such as oligopeptide-1, copper peptides, and botulinum-like peptides, BOC Sciences offers integrated solutions including peptide synthesis, encapsulation, sustained-release system design, and transdermal enhancement, accelerating the commercialization of functional skincare products.

BOC Sciences is committed to providing advanced technological support for the medical aesthetics industry, covering active ingredient development, delivery system design, formulation optimization, and quality control. With a strong foundation in chemical synthesis and bioengineering technologies, we create high-performance, stable solutions for medical aesthetic products that meet clinical and market demands, helping drive innovation and industry upgrades.

Medical aesthetic formulations require active ingredients with higher standards than traditional skincare products. These ingredients must have clear mechanisms, good biocompatibility, and clinical-grade stability. BOC Sciences offers the following services:

We offer a range of formulation development services tailored to different product needs, including but not limited to:

Medical aesthetic products often require active ingredients to penetrate the skin barrier and reach the target layers. BOC Sciences provides advanced skin delivery system designs, including:

The efficacy of cosmetics and medical aesthetic products largely depends on their stability. We conduct stability assessments following pharmaceutical-grade quality standards:

BOC Sciences operates GMP-compliant production workshops with full-scale manufacturing capabilities, from laboratory-scale trials to commercial production. Our facilities are equipped with advanced reaction systems, sterile filling lines, lyophilization systems, emulsification equipment, and high-precision filtration and purification systems, meeting the preparation requirements for various dosage forms (e.g., injectables, gels, microspheres, emulsions). The production environment is rigorously controlled according to ISO cleanroom standards, supporting sterile processing of high-potency ingredients and sensitive bioproducts. We offer one-stop GMP manufacturing services, including formulation verification, process transfer, release testing, and complete batch record systems, ensuring the quality, safety, regulatory compliance, and market efficiency of medical aesthetic and cosmetic products.

In the process of developing medical aesthetic and cosmetic formulations, precise quality testing is crucial for ensuring product safety, stability, and efficacy. BOC Sciences has established a systematic and standardized quality testing service platform, covering raw material identification, ingredient analysis, stability evaluation, particle contamination monitoring, and biocompatibility assessment. With advanced testing equipment and rigorous analytical methods, we provide reliable data support to accelerate the compliance process from product development to registration, enhancing the overall product quality assurance system.

BOC Sciences offers a one-stop formulation development service for medical aesthetics, biotechnology, and high-end cosmetics industries, covering raw material selection, formulation development, GMP manufacturing, and quality control testing. We aim to empower our clients with differentiated, high-performance, and market-oriented product solutions, applicable to diverse scenarios including clinical treatments, skincare, and anti-aging aesthetics.