Polycaprolactone (PCL) is a biocompatible and biodegradable synthetic polymer that has become one of the hot materials in the medical aesthetics field in recent years due to its excellent biocompatibility, biodegradability, low toxicity, plasticity, good mechanical properties, and biological activity. PCL microspheres, with their excellent biocompatibility, controllable degradation, and high design flexibility, are becoming an ideal platform for drug delivery, injection filling, tissue regeneration, and other applications. BOC Sciences is dedicated to providing global clients with customized PCL microsphere preparation and development services, with particle sizes ranging from 1 to 100 μm. We offer medical-grade, cosmetic-grade, and industrial-grade PMMA microspheres, fully supporting both research and commercial applications. We have advanced microsphere preparation technology, functional modification platforms, and a rigorous quality control system to provide customers with one-stop solutions from concept validation to mass production.

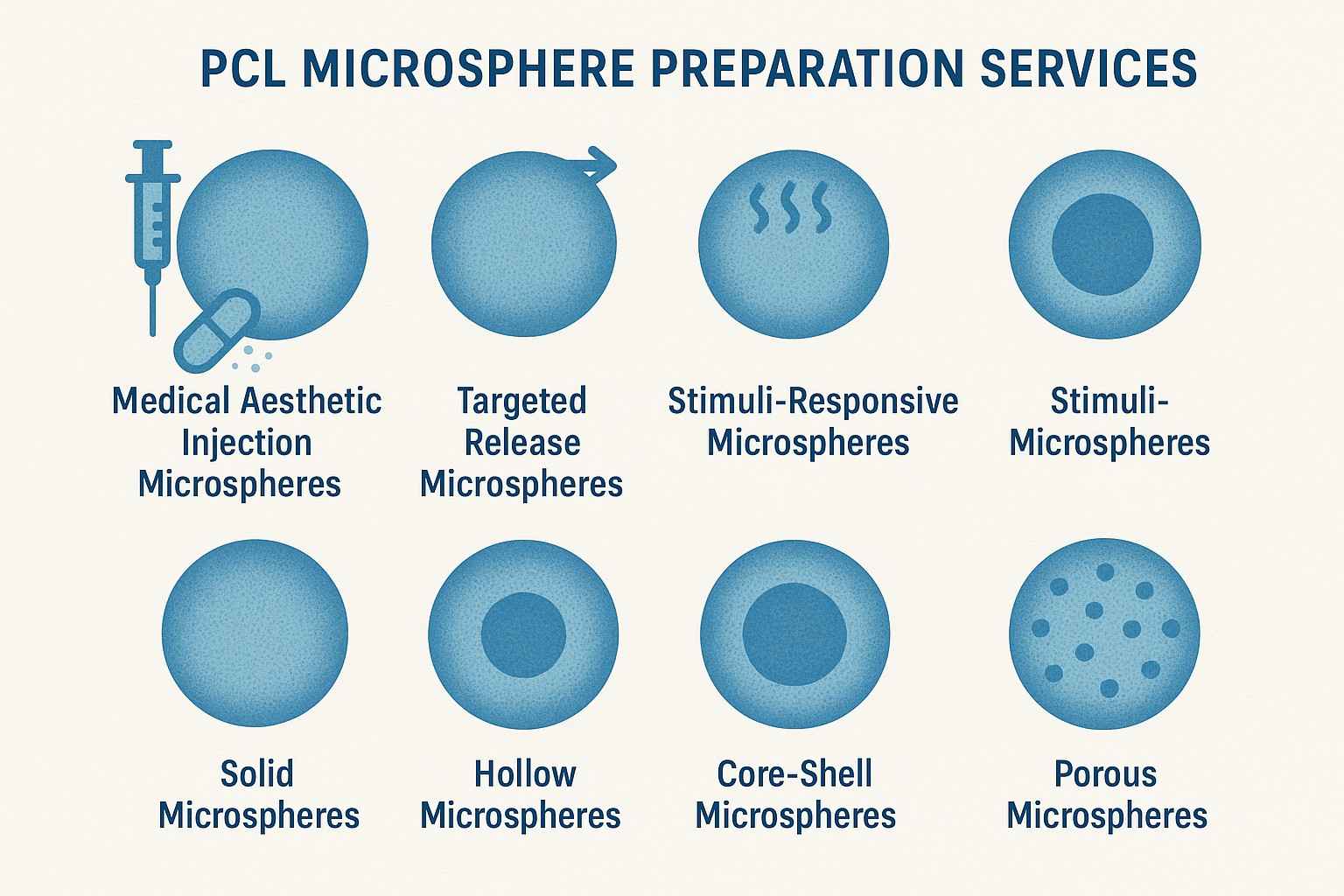

We offer tailored solutions for microsphere structure and function according to customer-specific needs, ensuring that application effects meet industry requirements, widely applied in medical aesthetics, drug delivery, and other fields.

We precisely control the particle size range of microspheres (1–100 μm), ensuring uniform particle size distribution and high reproducibility to meet precise size requirements for various applications such as injection filling and drug delivery.

We provide efficient encapsulation technology to ensure high encapsulation rates of drugs or active substances while achieving on-demand release, catering to various drug delivery needs, such as sustained release and targeted release.

We offer surface modification techniques such as PEGylation, hyaluronic acid, antibodies, and others, enhancing the biocompatibility, circulation stability, and targeting ability of microspheres, improving therapeutic effects and product performance.

We provide process optimization and scaling services from laboratory to pilot scale, ensuring process stability and meeting the technical requirements for large-scale production, facilitating smooth transitions from R&D to commercialization.

Equipped with advanced testing equipment, we comprehensively evaluate the particle size, surface characteristics, encapsulation rates, drug release profiles, etc., to ensure the quality stability and reliability of each batch of products.

We are able to precisely control and functionalize microspheres through advanced technologies and processes, ensuring perfect matching of particle size, distribution, and functional characteristics. Whether it is particle size control from 1 to 100 μm or efficient drug encapsulation with controllable release properties, we can provide high-quality products for our clients. We also offer surface modification and functionalization services, such as PEG modification and targeted ligand conjugation, to further enhance the biocompatibility and targeting ability of microspheres. Whether from small-scale trials to pilot studies, or large-scale production, our process optimization and scaling support ensure stable and controllable production.

BOC Sciences offers PCL microspheres that meet the standards of the medical aesthetics industry through precise process control, ensuring that microsphere particle size and morphology are perfectly suited for injection filling applications, with high biocompatibility, long-lasting stability, and non-invasive properties.

Combining advanced surface modification techniques, we can effectively conjugate targeting ligands (such as hyaluronic acid and antibodies) to the surface of PCL microspheres, achieving precise drug delivery and maximizing targeting and therapeutic efficiency.

By optimizing the structure and functional design of microspheres, BOC Sciences ensures efficient encapsulation of drugs and sustained, controlled release, meeting long-term sustained release and specific release needs, widely used in chronic disease treatment and sustained drug delivery.

We use advanced stimuli-responsive materials to prepare microspheres that respond to environmental changes (such as pH, temperature, etc.) and release encapsulated drugs or active substances under specific conditions, catering to smart drug delivery and controlled release needs.

BOC Sciences focuses on preparing highly stable solid PCL microspheres using efficient encapsulation technology to ensure long-term stability in complex environments, widely applied in drug loading, nutrient delivery, and biomedical research.

Our hollow PCL microspheres offer a larger encapsulation space, and their shell structure has been rigorously optimized to ensure superior performance in targeted drug delivery and biomedical fields, providing higher drug encapsulation rates and longer release times.

BOC Sciences can prepare core-shell PCL microspheres with high stability and biocompatibility, ensuring excellent performance in drug-controlled release, cell targeting, and biodegradability through internal and external layer functional designs.

Our porous PCL microspheres provide a larger surface area, optimizing drug encapsulation and release properties. They are widely used in cell culture, tissue engineering scaffolds, and drug delivery systems, offering superior biodegradability and biomedical application effects.

BOC Sciences' PCL microsphere preparation technology platform is highly flexible and advanced, able to select the most suitable preparation process based on customer-specific application needs. We offer multiple preparation technologies, including emulsion evaporation, spray drying, microfluidics, and solvent diffusion, to ensure that each microsphere meets ideal performance and quality. Whether it is precise control of particle size and size distribution, or optimization of encapsulation rates and release characteristics, we can meet the needs of medical aesthetics, drug delivery, cosmetics, and biomedical fields through precise process control. Through continuous optimization of preparation processes, BOC Sciences can provide full process support from small trials to pilot studies and even large-scale production, ensuring efficient, stable production and high-quality end products.

Emulsion evaporation is a commonly used PCL microsphere preparation technology at BOC Sciences. By precisely controlling the solvent evaporation rate, we ensure uniform particle size and distribution of PCL microspheres. We can efficiently encapsulate active ingredients in this process to meet the needs of drug-controlled release and targeted delivery.

Spray drying atomizes the solution and quickly evaporates the solvent, making the production process efficient and simple, enabling the rapid preparation of uniform microspheres with controllable particle size. BOC Sciences uses this method to achieve large-scale production, with flexible adjustments in microsphere structure and function.

Microfluidic technology allows precise control of the microsphere preparation process, especially suitable for microsphere production that requires precise particle size control and complex surface modification. BOC Sciences has deep technical expertise in this area, capable of producing high-quality, functionalized microspheres.

Solvent diffusion demonstrates excellent performance in controlling microsphere particle size and encapsulation rates. By optimizing solvent diffusion rates and environmental conditions, BOC Sciences can achieve efficient encapsulation and stable control of drug release, suitable for the biopharmaceutical and cosmetic industries.

In the functional modification of PCL microspheres, BOC Sciences offers a variety of customized services, including side group and end group functionalization, PEGylation, targeted ligand modification, and bioconjugation reactions. These modification methods can endow PCL microspheres with specific biocompatibility, targeting abilities, and extended in vivo circulation time to meet different research and clinical needs. Additionally, BOC Sciences provides surface protection services for PCL microspheres to prevent unwanted side reactions. Using advanced analytical platforms such as DLS, TEM, HHPLC, etc., we assess microsphere characteristics such as particle size, surface potential, and drug encapsulation rates, ensuring the stability and reproducibility of the modification effects.

BOC Sciences provides comprehensive microsphere quality testing and performance evaluation services, dedicated to ensuring that every batch of microsphere products meets strict industry standards for structure, functionality, and stability. Our quality testing includes evaluations of basic performance metrics such as microsphere particle size, distribution, and encapsulation efficiency, as well as advanced analysis of surface modification, drug release rates, and biocompatibility. With high-precision testing methods, we provide detailed performance characterization to help clients optimize product design, ensuring the reliability and effectiveness of microspheres in real-world applications. Furthermore, our testing services cover all stages, from small-scale trials to pilot and large-scale production, offering full quality monitoring throughout the process to ensure product consistency and high-quality output.

Due to its unique biocompatibility, biodegradability, and controllable release characteristics, PCL microspheres are widely applied across multiple industries, particularly in biomedicine, cosmetics, and medical aesthetics. Leveraging advanced microsphere preparation technology and functional design, BOC Sciences can provide customized PCL microsphere solutions to meet diverse application needs. The microsphere products we offer are suitable for biomedical applications such as drug delivery, tissue engineering, and targeted therapy, as well as important roles in cosmetic active ingredient delivery and injectable filler materials in medical aesthetics. Whether in controlled drug release, regenerative medicine, or skin care and cell therapy, BOC Sciences' PCL microspheres provide efficient solutions to ensure product precision, stability, and long-term effectiveness.

Polycaprolactone (PCL) is a synthetic polymer synthesized through the ring-opening polymerization of ε-caprolactone monomer. It is a linear, semicrystalline polymer with excellent biocompatibility, processability, and biodegradability. PCL has widespread applications in various fields, particularly in drug delivery, tissue engineering, and environmental protection. Due to its low melting point and good mechanical properties, PCL is commonly used to prepare microspheres, scaffolds, and films.

Yes, Polycaprolactone (PCL) is biodegradable. Its degradation process mainly occurs through hydrolysis, with the resulting products eventually broken down by microorganisms into harmless substances. Because PCL degrades slowly, typically over several months to years, it is considered an environmentally friendly material and is widely used in fields such as biomedicine, packaging, and agriculture.