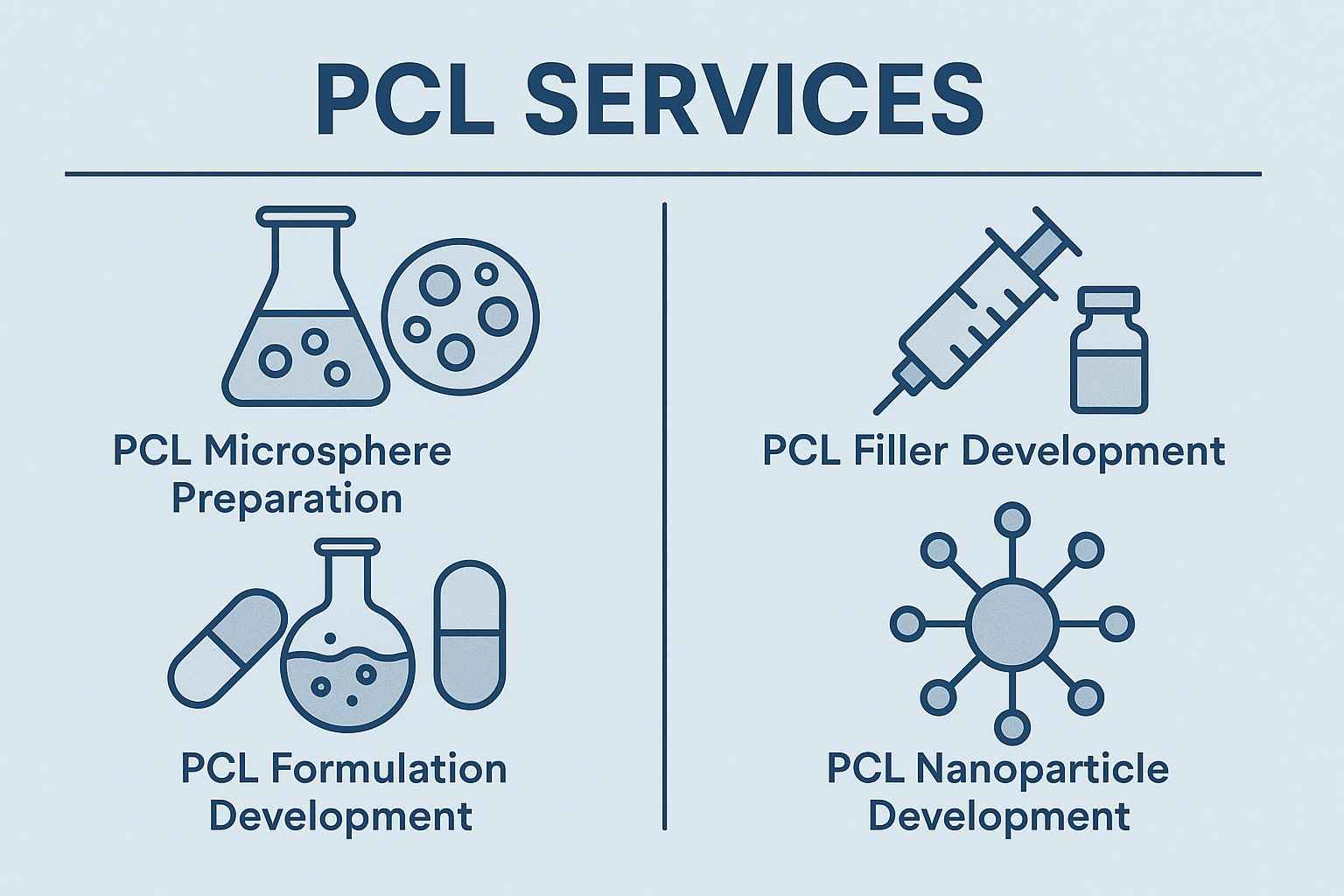

BOC Sciences is committed to providing high-quality custom development and preparation services for polycaprolactone (PCL) and its microsphere formulations to clients in industries such as medical aesthetics, cosmetics, and biomedicine. Our services cover medical-grade, cosmetic-grade, and industrial-grade PCL materials and microspheres, including PCL microsphere preparation and modification, PCL nanoparticle development, PCL hydrogel systems, PCL filler design, and PCL formulation development. We also offer systematic quality testing and in vivo and in vitro biological evaluation services. Leveraging an advanced material synthesis platform and a standardized quality control system, BOC Sciences provides a one-stop solution from early-stage R&D to GMP manufacturing, supporting the commercialization of high-value-added products in next-generation material science.

Focused on the particle size control and uniformity of PCL microspheres for medical aesthetic uses, meeting the professional needs of injection filling and durable repairs.

Providing a variety of PCL products ranging from medical-grade to cosmetic-grade and industrial-grade, meeting the development standards for different formulations across industries.

Supporting the parallel development of PCL nanoparticles and hydrogels to meet the needs of controlled-release drug delivery, skin penetration, and regenerative medicine.

Enabling physical encapsulation, surface grafting, and functional modification to enhance the bioactivity and targeting ability of PCL microspheres.

Equipped with a cGMP-certified production environment and a comprehensive quality control system, supporting large-scale production and registration filings.

Providing full-process services from in vivo and in vitro evaluation to efficacy testing, helping clients achieve product compliance and efficient market entry.

BOC Sciences possesses an advanced polymer materials platform and an interdisciplinary R&D system, committed to offering high-quality custom development services for PCL and its microsphere formulations in biomedicine, medical aesthetics, and cosmetics. We not only achieve the fine synthesis of basic PCL raw materials but also provide development support for various formulation forms, including microspheres, nanoparticles, hydrogels, and fillers, according to customer needs. Our services cover material modification, formulation optimization, process scale-up, and biological performance evaluation, assisting clients in accelerating product transformation and market launch.

BOC Sciences can synthesize PCL microspheres within a range of particle sizes (1 μm to 100 μm) according to customer needs, widely used in controlled-release drug carriers, skin filling materials, and cosmetic active ingredient encapsulation. We use processes such as emulsion polymerization, spray drying, and solvent evaporation to precisely control particle size uniformity, encapsulation efficiency, and degradation rates.

To meet specific application needs, we offer various modification strategies, including surface functionalization (carboxyl/amino), shell coating (PEGylation, PLGA encapsulation), adding hydrophilic/hydrophobic adjustment components, and drug release regulation layers (e.g., sustained-release coatings). These technologies help improve the tissue compatibility, drug release performance, and targeting ability of microspheres.

BOC Sciences has a mature platform for PCL nanoparticle preparation, suitable for encapsulating small molecules, proteins, peptides, etc. Common applications include transdermal absorption, targeted drug delivery, and nanoparticle-based cosmetic systems. We offer highly dispersive nanoparticles with particle sizes<200 nm and PDI <0.2, supporting encapsulation efficiency and drug release curve customization.

Based on the copolymerization or crosslinking strategies of PCL and hydrophilic polymers, we have developed a series of PCL hydrogel systems with both mechanical strength and biodegradability. These are widely used in tissue engineering scaffolds, facial mask substrates, skin repair patches, and other fields. We can regulate the gel strength, crosslinking density, release behavior, and degradation cycle.

We provide several PCL-based injectable or topical filler development services for medical aesthetic clients. We can customize physical parameters such as particle size, viscoelasticity, and degradation cycle based on the client's target area requirements, ensuring the biological safety and tissue affinity of the products. These have been applied to facial contour restoration, skin smoothing, and anti-aging products.

BOC Sciences offers PCL-based composite formulation development services, including the design of composite systems blended with various polymers (e.g., HA, PLGA, PEG). We can regulate the rheological properties, release characteristics, and physical stability of the system to meet different clinical or cosmetic needs.

BOC Sciences possesses a full-process PCL microsphere formulation manufacturing capability, ranging from laboratory R&D, pilot scale-up, to industrial-scale production. We are equipped with GMP-compliant manufacturing facilities, including clean areas, closed reaction systems, high-precision emulsification equipment, spray drying and freeze-drying systems, ensuring the preparation of products in a sterile and stable environment. Additionally, we have pilot-scale and large-scale production capabilities, from material screening and small-batch validation to commercial-scale production. The company strictly adheres to GMP quality systems under ICH and FDA guidelines, covering raw material traceability, process validation, environmental monitoring, and batch release, providing high-quality, traceable, and registerable PCL microsphere products for medical aesthetic, cosmetic, and biomedical clients.

BOC Sciences has established a comprehensive quality testing system, covering the physical and chemical properties, biological performance, and in vivo and in vitro behavior of raw materials, intermediates, and final products. We are equipped with advanced analytical instrumentation platforms, including particle size analyzers, scanning electron microscopes (SEM), thermal analyzers (DSC/TGA), nuclear magnetic resonance (NMR), Fourier-transform infrared spectroscopy (FTIR), high-performance liquid chromatography (HPLC), and more, enabling multidimensional performance characterization. We also offer in vitro release, degradation kinetics, cell compatibility, animal testing, and other evaluation services in compliance with ICH and ISO standards, providing strong data support for PCL microsphere registration and clinical transformation. BOC Sciences is committed to providing clients with high-quality, full-process, one-stop testing solutions.

As a biodegradable, highly biocompatible aliphatic polyester material, PCL is widely used in the fields of medical aesthetics, cosmetics, and biomedicine due to its controllable degradation, excellent mechanical strength, and flexible modification options. Particularly, the innovative development of various formulations, such as PCL microspheres, nanoparticles, and hydrogels, has shown great potential in numerous applications, including facial filling, skin regeneration, active ingredient controlled release, tissue engineering, and vaccine delivery. BOC Sciences offers customized PCL products and formulation development solutions to help clients achieve innovative integration of precise treatment, aesthetic repair, and smart skincare, accelerating product clinical transformation and market deployment.

Polycaprolactone (PCL) is a low-toxicity, highly biocompatible synthetic polymer material that degrades slowly into non-toxic small molecules in the body. It is widely used in medical aesthetics, drug delivery, tissue engineering, and other fields. Extensive research and clinical data show that PCL is non-toxic and non-sensitizing to humans, making it a recognized safe material.

In medicine, polycaprolactone is used for absorbable sutures, orthopedic scaffolds, injectable fillers, controlled-release drug carriers, and tissue engineering scaffolds. Its controllable degradation and excellent biocompatibility make it an ideal material for regenerative medicine and personalized healthcare, supporting diverse applications from wound repair to cancer treatment.

Polycaprolactone is used in dentistry for alveolar bone repair scaffolds, degradable dental membranes, root canal filling materials, and more. Due to its slow degradation properties and biocompatibility, PCL promotes periodontal tissue regeneration, supports the structural stability of bone substitute materials, and is developed as a carrier in dental aesthetic products to aid in dental regeneration and functional recovery.

The PCL repair technique utilizes the degradability and good biocompatibility of polycaprolactone, widely applied in tissue repair and regenerative medicine. Common PCL repair techniques include using PCL scaffolds to promote tissue or bone regeneration, applied in wound repair, soft tissue regeneration, etc. As a scaffold material in orthopedics, dentistry, and skin regeneration, PCL gradually degrades in the body while providing structural support for new tissues.

Liquid PCL is safe under appropriate conditions, especially in medical and biomedical applications. It is commonly used in drug delivery systems, injectable fillers, and wound dressings. Liquid PCL has good biocompatibility and can degrade into non-toxic small molecules in the body, usually not causing toxic reactions. However, quality and concentration must be strictly controlled during use to ensure safety.

PCL injectable refers to polycaprolactone used as a carrier or filler material applied through injection in medical aesthetics and therapeutic fields. It can be used for facial contour shaping, wrinkle filling, or promoting skin repair. PCL injectables provide long-lasting, sustained-release effects with good biocompatibility, remaining active for months or even over a year after injection, gradually being absorbed by the body.