Polycaprolactone (PCL) nanoparticles have gained wide acceptance in drug delivery systems and tissue engineering applications as well as medical coatings because of their outstanding biocompatibility combined with their degradable nature and customizable physicochemical properties. BOC Sciences utilizes its deep knowledge in advanced chemical synthesis and preparation to provide development services for PCL nanoparticles with sizes spanning from 100 nm to 1000 nm. Our technology enables precise control over nanoparticle size, surface properties, and drug loading capacity to fulfill particular application needs. Our R&D team specializes in delivering tailor-made solutions through the design of suitable nanoparticle structures and functional modifications that meet customer specifications while operating across drug delivery systems, tissue engineering, medical imaging, and cosmetics.

Nanoparticles with excessively large or uneven sizes can affect the biocompatibility and drug delivery efficiency of PCL nanoparticles. BOC Sciences optimizes preparation processes, such as solvent evaporation and emulsion polymerization, to precisely control particle size and distribution, ensuring consistency and stability to meet different application needs.

Efficient drug loading and release control can be challenging, particularly in maintaining drug stability and controlled release. BOC Sciences employs various techniques, such as surface modification and optimized drug loading methods, to achieve precise control over drug loading and release, ensuring effective drug release at the target site.

Surface modification significantly influences the stability and biocompatibility of nanoparticles, making it difficult to balance different requirements. BOC Sciences offers various surface treatment technologies, such as PEGylation and targeted molecular modification, to enhance the stability and specificity of PCL nanoparticles, meeting diverse clinical and industrial needs.

The degradation rate of PCL nanoparticles may not match the drug release rate, affecting efficacy and safety. BOC Sciences precisely controls PCL molecular weight and particle size to optimize the balance between degradation rate and drug release, ensuring that the product degrades safely in the body without toxicity.

Maintaining consistency and stability in product quality from laboratory scale to large-scale production can be challenging. BOC Sciences uses automated production equipment and a strict quality control system to ensure the quality stability of each batch of PCL nanoparticles, ensuring a smooth transition from small batches to large-scale production.

Efficient nanoparticle production is often associated with higher costs, impacting market competitiveness. BOC Sciences reduces production costs and enhances efficiency through process optimization and refined production management, providing cost-effective PCL nanoparticle solutions to meet different market needs.

BOC Sciences understands that different customers have varying requirements for PCL nanoparticles in different application areas. Therefore, we provide tailored solutions for each customer, ensuring that the products we offer meet their specific needs across multiple dimensions through flexible production models and innovative technologies. BOC Sciences values long-term stable collaborations with clients, providing detailed progress reports at each project stage and making real-time adjustments based on client feedback. This efficient communication and project management model ensures smooth development and on-time delivery of high-quality products. Our customized services include but are not limited to:

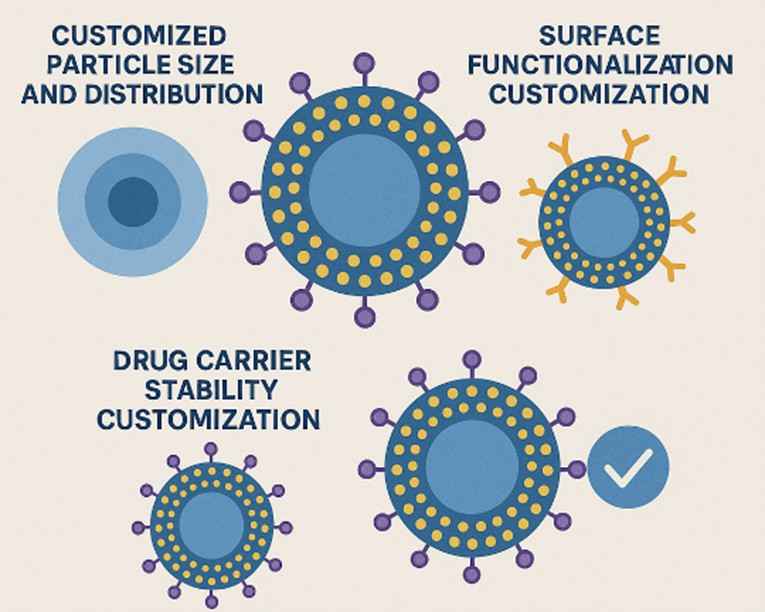

According to customer application needs, BOC Sciences can adjust the particle size range of PCL nanoparticles, typically from tens to hundreds of nanometers. For drug delivery systems, particle size plays a crucial role in the release rate and efficacy of the drug in vivo. BOC Sciences can optimize the particle size based on the physicochemical properties of different drugs to achieve the best drug release performance.

To meet various drug delivery, targeted therapy, and other specific needs, BOC Sciences can modify the surface of PCL nanoparticles according to customer requirements. These modifications include but are not limited to the introduction of hydrophilic groups, PEGylation, and other targeted molecular modifications, such as antibodies, peptides, or small molecules, which can significantly improve the biological distribution of the nanoparticles.

BOC Sciences can also adjust drug loading and optimize the stability of PCL nanoparticles based on customer needs. This is particularly crucial for drug delivery systems, especially in long-term storage and transportation, where the stability of the drug carrier directly impacts the drug's efficacy.

Whether it is small-scale samples for the R&D phase or large-scale commercial production, BOC Sciences can offer services ranging from laboratory-scale to industrial production. For batch production, BOC Sciences has a strict batch management system to ensure consistency in composition and performance across each batch of PCL nanoparticles.

The PCL nanoparticle preparation services offered by BOC Sciences combine advanced nanotechnology, strict quality control systems, and a variety of adjustable preparation methods to provide customized solutions based on the specific needs of customers. The preparation process ensures product quality and meets the application needs in drug delivery, material synthesis, and other fields. Additionally, BOC Sciences offers personalized customization services, adjusting preparation processes based on customer requirements for particle size, morphology, surface characteristics, and more, ensuring maximized product performance.

The emulsion-solvent evaporation method is one of the common techniques for preparing PCL nanoparticles. BOC Sciences uses this method to dissolve PCL in an organic solvent, emulsify it into a water/oil emulsion, and then evaporate the solvent to form stable PCL nanoparticles. This method offers high yield and good particle size distribution, making it suitable for large-scale production.

In this method, PCL is dissolved in a solvent, and the solvent is gradually diffused into the aqueous phase to form nanoparticles. By precisely controlling the diffusion rate of the solvent, nanoparticles with uniform size can be obtained. BOC Sciences utilizes efficient ultrasonic technology in this process to ensure particle uniformity and stability.

Spray drying is an efficient preparation method suitable for large-scale nanoparticle production. BOC Sciences uses a spray device to atomize PCL solution and rapidly evaporate the solvent in a drying airflow to obtain nanoparticles. This method enables the rapid production of smaller particles with high production efficiency.

The ultrasonic method uses high-frequency vibrations from ultrasonic waves to disperse PCL solution into nanoparticles. BOC Sciences combines ultrasonic dispersion technology to quickly obtain high-quality PCL nanoparticles, suitable for small batch and high-precision preparation needs.

BOC Sciences has robust GMP manufacturing capabilities to support the production of PCL nanoparticles from small-scale R&D to large-scale production. Our GMP facilities are equipped with advanced equipment and automated systems, allowing effective control of every detail in the production process, including raw material procurement, manufacturing processes, quality monitoring, and final product packaging. Through efficient process management and quality control, BOC Sciences ensures that each batch of PCL nanoparticles meets strict quality standards. Whether in small-scale laboratory production or large-scale manufacturing to meet market demand, we provide flexible production solutions to help clients smoothly transition to industrial production stages.

BOC Sciences places a strong emphasis on quality control throughout the preparation of PCL nanoparticles, ensuring that each batch meets stringent quality standards and satisfies the specific needs of our clients. Quality control is integrated into the entire production process, from raw material procurement to final product delivery. BOC Sciences implements comprehensive monitoring and management measures. In addition, based on customers' personalized requirements, BOC Sciences offers tailored solutions to ensure the performance of the product aligns with the customer's application standards and expectations.

As a high-performance nanomaterial, PCL nanoparticles have found widespread applications due to their excellent biodegradability, good biocompatibility, and adjustable physicochemical properties. Especially in drug delivery systems, medical devices, cosmetics, and food additives, PCL nanoparticles demonstrate tremendous potential. With controllable particle size, surface properties, and loading capacity, PCL nanoparticles can achieve precise targeted delivery and sustained release effects, improving the therapeutic efficacy of drugs while reducing side effects. Furthermore, PCL nanoparticles are widely used in tissue engineering and regenerative medicine, making them ideal carriers for promoting cell growth and tissue repair. BOC Sciences is committed to providing high-quality, customized PCL nanoparticle solutions to advance their broad application and development across various industries.

Polycaprolactone (PCL) is a biodegradable polymer widely used in drug-controlled release systems, tissue engineering scaffolds, sutures, degradable packaging materials, and 3D printing. Its excellent biocompatibility, low melting point, and mechanical properties make it highly flexible and adaptable for both medical and industrial applications.

PCL nanoparticles, due to their good drug encapsulation capacity and biodegradability, are commonly used in targeted drug delivery, sustained release systems, gene delivery, vaccine carriers, anticancer drug transport, and tissue repair materials. They effectively protect active ingredients, prolong the therapeutic effect, and improve the targeting and bioavailability of treatments.

Common methods for preparing PCL nanoparticles include emulsion evaporation, nanoprecipitation, double emulsion, and solvent diffusion methods. These methods optimize particle size control and stability by adjusting factors such as solvent, stirring speed, and surfactants, catering to different drug load and release requirements.