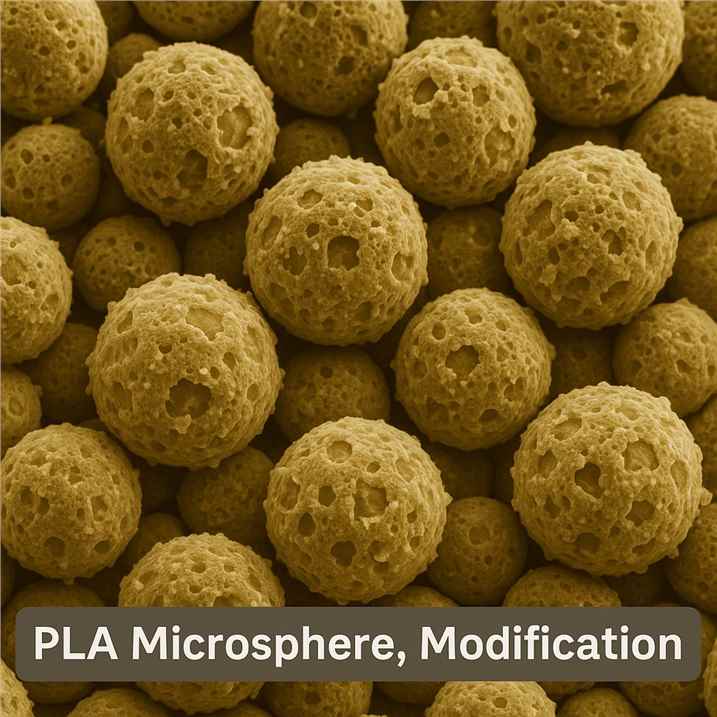

BOC Sciences is dedicated to providing high-end polylactic acid (PLA) microsphere (PLLA and PDLLA) modification services to global clients, covering the full process from material design to microsphere structural optimization. Leveraging extensive experience in polymer modification, we enhance microsphere performance in drug delivery, slow release of active ingredients for skincare, tissue repair, and medical aesthetics by controlling molecular structure, particle size and morphology, surface functionalization, optimizing encapsulation and controlled release properties, and regulating biodegradation behaviors. The modification solutions provided by BOC Sciences are flexible and precise, allowing for targeted development for different application scenarios, helping clients achieve breakthroughs in product performance and enhance clinical or market value.

Through precise emulsification technology and microfluidic processes, we can control the microsphere particle size within a range of 200 nm to 100 μm, ensuring consistency and stability in different applications.

Using advanced copolymerization modification technology and membrane encapsulation processes, we improve the encapsulation rate of drugs or active ingredients to over 90%, while adjusting release curves to achieve optimal efficacy.

We provide multiple surface modification methods, such as plasma treatment, chemical grafting, and others, to efficiently fix drugs, antibodies, or peptides onto the microsphere surface, ensuring targeted effects.

By precisely designing the ratio of PLA and other hydrophilic copolymer monomers, we control the hydrophilic/hydrophobic balance of the microspheres, meeting the demands for different drug carriers, skin permeability, and biocompatibility.

We design multiple degradation mechanisms to ensure the microspheres' degradation rate can be controlled in both the biological system and external environments, while maintaining stability and functionality during use.

By integrating advanced technologies such as HPLC, LC-MS, FTIR, and NMR, we provide comprehensive quality testing services for each batch of products, ensuring microspheres meet international standards and satisfy customers' precise requirements.

BOC Sciences' PLA microsphere functional modification services are designed to meet the high-performance carrier material demands of industries such as biomedicine, cosmetics, and medical aesthetics through advanced technology. We provide surface modification, copolymerization modification, carrier encapsulation, stimuli-responsive functionality, magnetic functionality, and fluorescent functionality, among other functional modification solutions, through precise molecular design and process optimization. These services not only significantly improve microsphere targeting and biocompatibility but also enhance their application performance in drug release, tissue repair, skincare, and regenerative aesthetics. With our years of research and industry accumulation, BOC Sciences offers customized solutions to meet diverse microsphere performance needs across different application scenarios.

By introducing surface functional groups such as carboxyl, amino, PEG chains, antibodies, peptides, or oligonucleotides, we can achieve requirements for cell targeting, improved hydrophilicity, or composite loading. Supports chemical grafting, plasma treatment, wet grafting, and other methods.

Through the regulation of PLA with copolymer monomers such as PLGA, PCL, PEG, and HEMA, we achieve controllable degradation, flexibility, and hydrophilic/hydrophobic balance in microsphere structures, particularly suited for drug loading and tissue engineering scaffold construction.

Supports the encapsulation of small molecule drugs, peptides, alkaloids, proteins, nucleic acids, and cosmetic active ingredients (such as hyaluronic acid, niacinamide, vitamin C), with customizable release cycles (from hours to several weeks).

By introducing pH-responsive materials, temperature-sensitive polymers, and enzyme degradation modules, we enable targeted release and responsive degradation of microspheres in specific environments such as tumor tissues, wound areas, or deep skin layers.

We introduce Fe₃O₄ or other nano-magnetic particles into the microsphere structure, enabling targeted delivery and positional control under an external magnetic field, suitable for precise drug release and integrated diagnostic and therapeutic systems.

We introduce fluorescent probes such as BODIPY, FITC, and Cy5 for cell tracking, skin penetration experiments, and in vivo distribution studies, providing visual evaluation methods for biomedical and cosmetic product development.

BOC Sciences possesses strong technical capabilities in PLA microsphere modification. Through advanced molecular design and precise process control, we offer efficient, customized microsphere modification solutions for various industry clients. We precisely regulate PLA microspheres' particle size, morphology, biocompatibility, and degradation rate, among other properties, to meet strict industry requirements. Additionally, we have accumulated rich experience in controlling microsphere shell thickness and release rates, providing optimized drug delivery systems and sustained release platforms for pharmaceutical, tissue engineering, and medical aesthetics fields.

By adjusting the PLA chain length, D/L isomer ratio, and the type and ratio of copolymer monomers, we can direct the control of microsphere material degradation behavior, mechanical properties, and hydrophilic/hydrophobic properties.

Using high-shear emulsification, microfluidic methods, solvent evaporation, membrane emulsification techniques, etc., we precisely control particle size distribution (from 200 nm to 100 μm) and can achieve various microsphere structures such as spherical, hollow, core-shell, wrinkled, and star-shaped.

By modifying terminal groups, copolymer chain design, and introducing degradation accelerators, we ensure that microspheres have controllable degradation cycles (from hours to months) in different tissue environments, with non-toxic biodegradable products.

We support multiple emulsification processes (W/O/W, O/W/O) to adjust shell thickness and core-to-shell ratios, improving the encapsulation efficiency of drugs/active substances (up to over 90%) and optimizing their release kinetics.

BOC Sciences offers PLA microsphere quality control services, aimed at ensuring the stability and consistency of every batch of microsphere products through advanced testing technologies and strict quality control standards. Our quality testing services cover the entire process from raw material procurement to final product delivery, ensuring that PLA microspheres perform excellently in various application scenarios. Whether for drug delivery performance, biocompatibility in tissue engineering, or skin penetration in cosmetics, we provide comprehensive testing support to ensure products meet international standards and industry regulations. With a strong technical team and advanced testing equipment, BOC Sciences delivers precise and reliable results to help customers optimize product quality and enhance market competitiveness.

The high-performance PLA microspheres we provide not only perform excellently in biomedical fields such as drug delivery and tissue repair but also enhance product efficacy and stability in the cosmetics and medical beauty industries. Through precise modification, our PLA microspheres meet the specific needs of various applications, providing customized solutions to help clients achieve leadership in their respective industries. Whether innovating drug delivery systems, optimizing skin care product penetration, or applying microencapsulation technology, BOC Sciences offers robust support.

PLA (polylactic acid) can be chemically modified in several ways to enhance its properties, including copolymerization, grafting, and crosslinking modifications. Copolymerization with other monomers, such as glycolide or lactide, improves the toughness, thermal stability, and biodegradation rate of PLA; grafting modification introduces hydrophilic or antioxidant functional groups, optimizing compatibility with other materials; crosslinking modifications help improve the mechanical strength and thermal stability of PLA, widely used in drug delivery and tissue engineering.

Impact modifiers for PLA include rubber-based additives (such as styrene-butadiene-styrene (SBS) triblock copolymers), polyether esters, and polyester modifiers. These modifiers increase the toughness, impact resistance, and processability of PLA, addressing its brittleness and expanding its applications in biomedical, packaging, and automotive industries.

PLA is biocompatible due to its simple chemical structure, non-toxic nature, and its ability to be naturally metabolized by the human body. Its biodegradability allows it to break down into harmless lactic acid and be expelled through respiration. PLA's biocompatibility makes it widely used in medical fields such as drug delivery systems, sutures, and tissue engineering scaffolds.

PLA polymerization is typically achieved through ring-opening polymerization (ROP). In this process, lactide monomers or their lactide precursors (such as L-lactide) undergo a ring-opening reaction in the presence of a catalyst, forming linear or branched polymers. The polymerization reaction can occur under different temperature and catalyst conditions, yielding PLA with specific molecular weights and structural features for various industrial and medical applications.