We combine current scientific research insights to create cutting-edge formulations that fulfill application requirements across multiple sectors while boosting product effectiveness and competitive market advantage.

Our control over microsphere particle size distribution guarantees stability and uniformity across drug delivery and medical aesthetics applications, which enhances product performance.

Our advanced encapsulation technologies enable efficient loading of drugs, nutrients, and active substances to maintain bioactivity and control sustained release at specific locations.

Through surface alterations of microspheres, we improve their biological compatibility and tailor specific features to boost their attachment to particular cells or tissues.

The implementation of our quality management system covers all processes, from selecting raw materials to manufacturing products to meet international quality standards, which ensures product safety and effectiveness.

Our one-stop service platform bridges R&D and production with commercialization to address technical obstacles throughout each step and speed up lab-to-market transitions for clients.

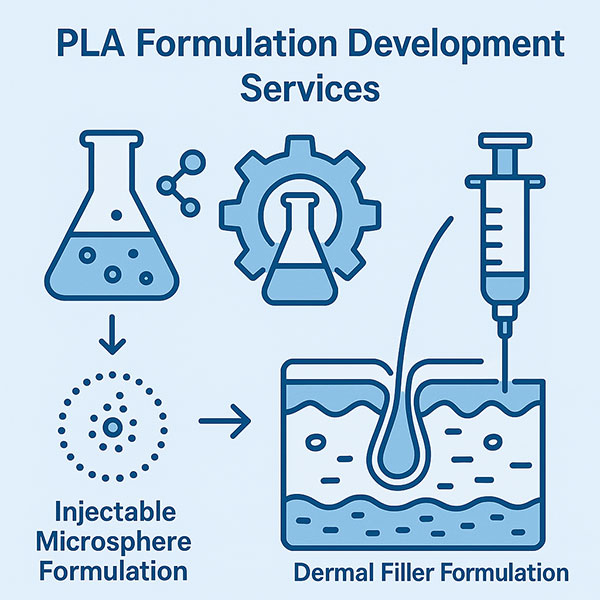

BOC Sciences designs PLA microsphere formulations tailored to customers' specific application scenarios. Whether for medical-grade, cosmetic-grade, or industrial-grade microspheres, we deliver high-quality, stable products to ensure optimal results in our clients' applications. Our formulation services include not only common microsphere suspension formulations but also composite injectable gel formulations, controlled-release particle formulations, and exfoliating particles. Each formulation undergoes rigorous process optimization to ensure superior performance and functional efficiency in practical applications.

BOC Sciences offers customized PLLA microsphere formulation development, focusing on optimizing drug delivery systems to ensure controlled and targeted drug release in vivo. We adjust particle size, drug loading, and degradation rate to provide efficient and safe therapeutic solutions.

BOC Sciences develops injectable PLA microsphere filler formulations for the medical aesthetics industry, optimizing microsphere size and surface characteristics to improve skin compatibility and comfort, prolong filling effects, and support anti-aging and wrinkle reduction goals.

We utilize microsphere technology to provide the cosmetics industry with stable active ingredient carrier solutions that delay release and enhance bioavailability. This technology is suitable for functional ingredients such as moisturizers, whitening agents, and antioxidants, ensuring long-term efficacy and product stability.

This formulation encapsulates active ingredients such as Vitamin C and retinol in PLA microparticles to achieve controlled release. Its advantages include improved stability, enhanced skin permeability, and prolonged effect duration, commonly used in controlled-release fragrances, sunscreens, and whitening agents.

We offer formulation development of PLA microspheres as biomedical scaffolds, optimizing degradation rates and cell compatibility to promote tissue regeneration and repair, helping clients develop efficient tissue engineering scaffolds that support rapid healing.

BOC Sciences provides custom microsphere formulations for bone tissue repair by loading bone-inducing factors (e.g., BMP) to enhance bone regeneration efficiency. Our technology ensures that the microspheres possess appropriate mechanical strength to support rapid repair and regeneration of bone defects.

This formulation consists of PLA microspheres combined with sterile water for injection, thickeners (e.g., CMC or gelatin), and stabilizers (e.g., mannitol). After injection, the microspheres stimulate collagen production, resulting in long-lasting filling effects widely used in facial filling and contouring.

The composite gel formulation combines PLA with hyaluronic acid and uses collagen or gelatin as a matrix. This formulation provides immediate filling effects after injection while promoting collagen production through PLLA, suitable for facial anti-aging and contour shaping.

BOC Sciences possesses advanced technical capabilities in PLA formulation development, offering high-quality customized solutions tailored to various application domains. Our technical advantages span material selection, structural design, microsphere molding, and particle size control, ensuring that each formulation achieves the desired outcome. Through precise technical control, we optimize the performance of PLA microspheres and enhance their applications in biomedical, cosmetics, and medical aesthetics fields.

We design the most suitable PLA microsphere materials through scientific material selection and structural optimization to meet application needs in drug delivery, medical devices, cosmetics, etc., maximizing their performance.

Using advanced molding processes, we precisely control microsphere size and morphology, ensuring uniformity and stability across applications and improving product performance and efficacy.

With innovative encapsulation technology, we efficiently load active ingredients into PLA microspheres and design advanced controlled-release systems to ensure sustained release and long-term effects at target locations.

Through surface modification techniques, we enhance the biocompatibility of microspheres and apply functional treatments as needed to improve in vivo performance, enhancing therapeutic or cosmetic outcomes.

Each formulation undergoes strict stability and safety evaluations, including in vitro tests and long-term storage assessments, ensuring the long-term stability and safety of the microspheres during use.

We provide full technical support from small-scale trials to pilot and large-scale production, ensuring a smooth transition to commercial manufacturing to meet market demands.

BOC Sciences possesses strong GMP manufacturing capabilities and is committed to providing customers with high-quality PLA formulation products that meet international standards. Our GMP-certified facilities are equipped with advanced production equipment and strict quality control systems, ensuring that each batch of PLA microspheres complies with industry requirements and client standards. Whether in pharmaceuticals, cosmetics, or medical devices, we offer customized formulation production services that meet cGMP requirements. In addition, our GMP manufacturing capabilities cover small-scale, pilot-scale, and large-scale production, allowing us to flexibly respond to production scale demands from different customers.

At BOC Sciences, we fully understand the importance of quality control for PLA formulations. To ensure that each batch of PLA microspheres meets international standards in terms of quality, stability, and safety, we provide comprehensive quality testing services. Our quality testing covers all stages from raw materials and production processes to final products, ensuring that every performance indicator of the product is rigorously tested. Using advanced testing equipment and techniques combined with an experienced quality control team, we precisely evaluate the key metrics of each formulation to meet the application needs of various fields. Our quality testing services for PLA formulations include the following items and instruments to ensure superior performance and reliable safety:

Due to their excellent biocompatibility, biodegradability, and controllable release properties, PLA microspheres are widely used in multiple fields, especially in biomedicine, cosmetics, and aesthetic medicine. BOC Sciences offers PLA formulation services that assist clients in developing innovative products tailored to industry demands. Whether in drug delivery, tissue repair, or as stabilizers in cosmetic and daily chemical products, PLA microspheres demonstrate vast application potential. The main applications of PLA in various fields include:

Polylactic acid (PLA) is a biodegradable polymer derived from renewable resources such as corn starch or sugarcane via fermentation. It is synthesized through the polymerization of lactic acid and widely applied in packaging, pharmaceuticals, textiles, and 3D printing. Thanks to its excellent biocompatibility and degradability, PLA is extensively used in environmentally friendly products.

PLA stands for polylactic acid. It is a bio-based polymer material formed by polymerizing lactic acid monomers. PLA can be made from renewable biomass sources like corn and sugarcane and is known for its good biodegradability, making it an environmentally friendly material.

Yes, polylactic acid (PLA) is biodegradable. It can be gradually decomposed by microorganisms in natural environments, typically fully degrading within several months to a few years depending on conditions such as temperature, humidity, and microbial activity. As such, PLA is widely used in eco-friendly packaging and medical devices.

Yes, polylactic acid (PLA) is non-toxic. As a bio-based material, PLA has good biocompatibility in the human body and is commonly used in medical devices and drug delivery systems. Since it is derived from natural raw materials and does not contain harmful chemicals, PLA is considered safe for use in applications involving human contact.