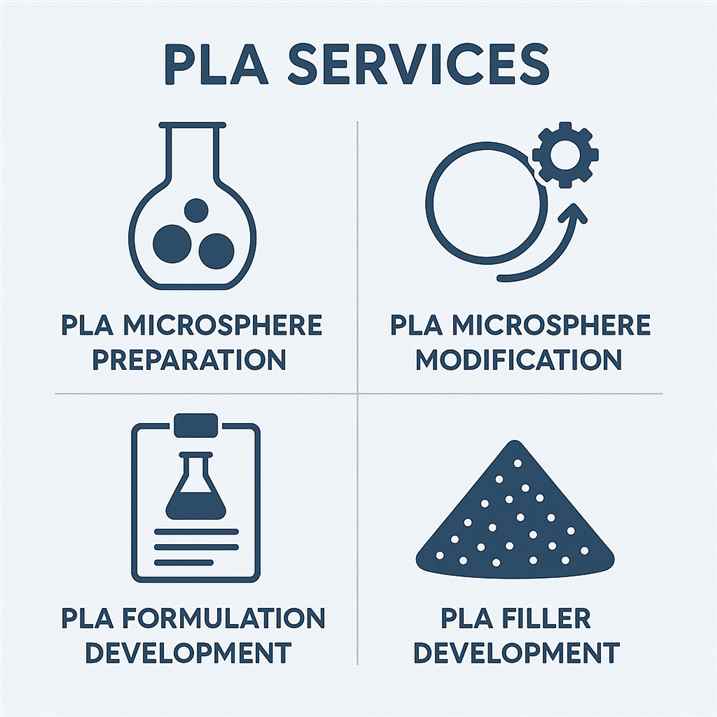

BOC Sciences is dedicated to providing professional services for the preparation and formulation development of polylactic acid (PLA) microspheres for cutting-edge applications in biomedicine, cosmetics, and aesthetic medicine. We possess the capability for R&D and large-scale production of medical-grade, cosmetic-grade, and industrial-grade PLA microspheres, covering preparation, modification, functional surface treatment, drug delivery system construction, and development of various PLA composite formulations. Additionally, we offer customized development of PLA-based fillers to meet clinical and aesthetic application needs such as anti-aging, skin regeneration, and tissue filling. Relying on an advanced material science platform and a GMP manufacturing environment, BOC Sciences provides full-process technical support from experimental development to industrial-scale production.

Utilizes medical-grade and cosmetic-grade PLA materials with high purity and low impurity levels to ensure biocompatibility and non-toxic degradation.

Capable of producing microspheres ranging from 10 nanometers to 100 micrometers, meeting requirements for injection, implantation, topical application, and more.

Offers various modification options including amination, carboxylation, and PEGylation, providing microspheres with targeting and environmental responsiveness.

Optimizes emulsification and encapsulation processes to achieve stable encapsulation and controlled release of small molecules and macromolecular actives.

Seamlessly transitions from gram-scale R&D to kilogram-scale GMP production, enabling customers to accelerate industrial transformation.

Equipped with full-process testing methods for particle size, morphology, and release behavior to ensure stable and reliable product quality.

As a biodegradable and biocompatible carrier material, PLA microspheres have been widely used in recent years in controlled drug release, cosmetic injections, skin repair, and sustained-release systems for active ingredients in skincare products. With strong material science R&D capabilities and advanced microsphere preparation technologies, BOC Sciences provides end-to-end PLA microsphere development services for the biomedicine, cosmetics, and aesthetic medicine industries—from basic formulation research to commercial scale-up. Tailoring development paths based on clients' product positioning and end-use requirements, we offer precise control of parameters such as microsphere size, loaded components, release duration, and surface modification, helping clients quickly build safe, effective, and controllable product systems and accelerate the transition from laboratory to clinic or market.

BOC Sciences is proficient in various microsphere preparation techniques, including solvent evaporation, double emulsion, and spray drying methods. We can produce microspheres with different particle sizes (10 nm to 100 μm) and morphologies (hollow, solid, porous) based on customer requirements. We support the encapsulation of various active components such as small-molecule drugs, peptides, proteins, nucleic acids, and botanical extracts, achieving precise controlled release.

To enhance the functionality and targeting capabilities of PLA microspheres, BOC Sciences offers a range of surface modification services. These include the introduction of functional groups such as carboxyl, amino, and PEG to enable binding with biomolecules, targeting ligands, or fluorescent probes, thereby improving cellular uptake efficiency, targeting capacity, or visual tracking performance. We also perform hydrophobic/hydrophilic interface adjustments to improve dispersion stability in various systems.

For the aesthetic medicine and cosmetics industries, BOC Sciences offers customized filler development services based on PLA microspheres, suitable for high-end cosmetic applications such as skin tightening, wrinkle reduction, and depression correction. We can control microsphere size, elastic modulus, and release characteristics and blend with auxiliary materials such as hyaluronic acid and collagen to achieve both structural support and active ingredient release. All formulations can undergo stability testing and safety evaluations according to customer requirements.

BOC Sciences has a well-established polymer carrier formulation development platform that helps clients customize PLA formulations best suited for the release behavior of their active ingredients. Our expert team will design appropriate molecular weight, copolymer ratio, microsphere structure, and excipient systems based on the physicochemical properties of the active ingredient, the characteristics of the target site, and the desired release duration, to construct stable, safe, and high-performance microsphere formulation solutions.

BOC Sciences owns advanced GMP-certified manufacturing facilities and has the ability to produce PLA microspheres at laboratory scale, kilogram scale, and even larger production volumes, fully supporting customers in transitioning from early-stage development to clinical and commercial phases. Our production system strictly complies with international quality standards such as ICH and ISO, covering cleanroom environment control, raw material traceability management, batch consistency verification, and aseptic processing. To meet the high-standard requirements of the biopharmaceutical, cosmetics, and aesthetic medicine industries, we provide personalized services for process transfer, scale-up validation, stability studies, and batch customization, ensuring that each batch of products achieves industry-leading safety, uniformity, and controllability. BOC Sciences is committed to becoming a trusted GMP manufacturing partner for PLA microspheres.

During the R&D and production of PLA microspheres, comprehensive and systematic quality testing is a critical step to ensure product safety, stability, and final efficacy. BOC Sciences has established a complete PLA microsphere quality testing platform, covering full-process quality control from raw materials and formulation intermediates to final products and application scenarios. Based on different project stages, we offer one-stop testing services ranging from physicochemical characterization to biological performance verification. These services meet the regulatory and market entry requirements for pharmaceuticals, cosmetics, and medical aesthetic products in terms of quality consistency, release mechanisms, safety, and more. All testing procedures comply with GLP or GMP standards, ensuring data authenticity and traceability, and support customized reporting, regulatory compliance consultation, and technical support.

Thanks to its excellent biodegradability, biocompatibility, and processability, PLA is emerging as a highly promising functional material in biomedicine and cosmetic products. BOC Sciences offers a variety of PLA-based application solutions based on market demands and application trends, covering multiple forms from microspheres to composite materials. These are widely used in key scenarios such as facial contour filling, skin repair, tissue regeneration, and cosmetic effect delivery. By tailoring PLA microsphere structure, release behavior, and composite system design, we help clients develop high-performance, personalized end products to enhance market competitiveness and customer satisfaction.

PLA injection is a cosmetic or medical treatment in which polylactic acid microspheres are injected into targeted areas to fill wrinkles, restore facial volume, and stimulate collagen production through controlled biodegradation.

Polylactic acid (PLA) degrades mainly through hydrolysis in the body or natural environment, where ester bonds are broken down into lactic acid monomers. Lactic acid is then metabolized into carbon dioxide and water by the human body, making PLA highly biodegradable. Its degradation rate is influenced by temperature, humidity, pH value, and material structure (such as molecular weight and crystallinity), making it widely applicable in absorbable implants and eco-friendly materials.

Polylactic acid is typically synthesized via ring-opening polymerization (ROP) of lactide or through direct polycondensation. The most common method involves using L-lactic acid or D,L-lactic acid as raw materials, polymerized in the presence of metal catalysts to produce high molecular weight PLA. The process allows control over molecular weight, stereoregularity, and final performance by adjusting reaction conditions, making it suitable for developing medical devices, drug carriers, and premium cosmetic materials.

Yes, PLA is widely used in drug delivery systems, especially for sustained and targeted delivery. Its biodegradability and biocompatibility make it an ideal carrier for small molecule drugs, proteins, and peptides. PLA microspheres or nanoparticles can be tailored in terms of particle size and degradation rate to achieve controlled release, effectively extending therapeutic duration, reducing side effects, and supporting various delivery forms such as injections, topical applications, and implants.