BOC Sciences possesses leading capabilities in peptide microsphere preparation and development, focusing on providing high-performance customized microsphere solutions for the pharmaceutical, cosmetics, and industrial sectors. The microspheres we offer not only meet the stringent standards for medical, cosmetic, and industrial use but also provide significant advantages in stability, controlled release, and biocompatibility. With advanced preparation technology, we can precisely control the microsphere's particle size, encapsulation efficiency, and release rate to meet the unique needs of different customers. Our microsphere products utilize various innovative materials and responsive mechanisms, such as pH responsiveness, thermosensitivity, and enzymatic degradation, ensuring optimal performance under specific conditions. Additionally, BOC Sciences excels in bulk production and quality control, ensuring that each batch of products reliably and efficiently delivers peptide active ingredients.

Peptide structures are sensitive and prone to inactivation due to heat, pH, or shear stress during the preparation process. BOC Sciences optimizes gentle processes and encapsulation strategies to protect peptide activity, enhancing product stability and preserving biological functionality.

Particle size impacts release rate and injection performance, often resulting in uneven distribution due to unstable processes. We employ precision techniques such as microfluidics and membrane emulsification to precisely control the particle size range, achieving high consistency between batches.

Conventional processes often lead to low encapsulation rates and significant drug leakage. BOC Sciences improves the emulsion-solvent evaporation technique and material modification to enhance encapsulation efficiency and controlled release, enabling precise drug delivery.

Organic solvents are widely used in microsphere preparation, but excessive residue can impact biological safety. We optimize drying and solvent removal processes, coupled with precise detection methods like gas chromatography (GC), to ensure solvent residues are within regulatory limits.

From laboratory to pilot scale, product inconsistency often arises from imperfect process transfer. BOC Sciences follows the Quality by Design (QbD) approach, providing complete process validation and scale-up solutions to ensure stable production under GMP conditions.

Peptides are difficult to penetrate barriers and are often degraded by enzymes, impacting efficacy. We design targeted materials and functionalized encapsulating layers to enhance microsphere permeability and sustained action in skin or in vivo systems, improving therapeutic effects.

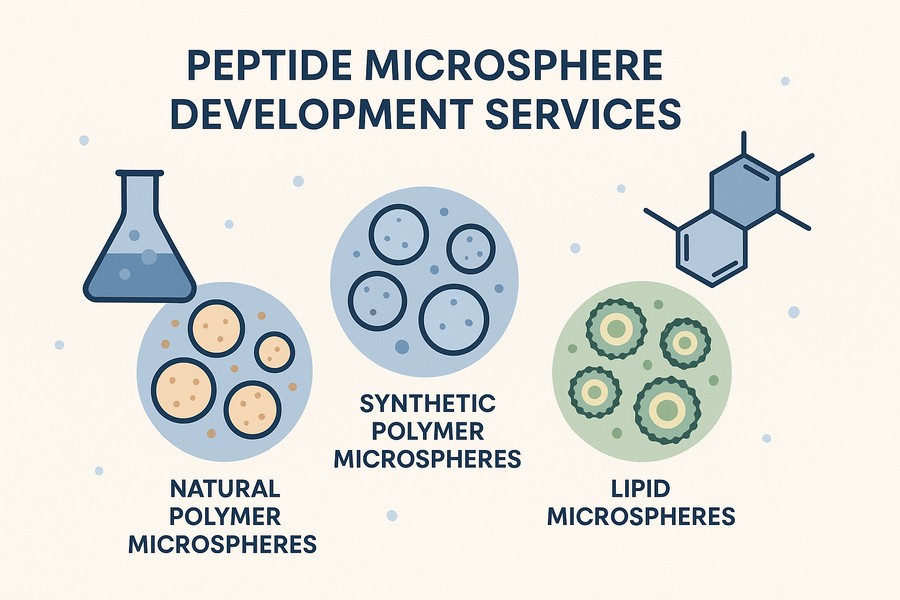

BOC Sciences provides comprehensive peptide microsphere development services, covering natural polymers, synthetic polymers, lipid microspheres, and various responsive microsphere systems. We are committed to offering customized peptide delivery platforms that meet the needs of industries such as medical aesthetics, cosmetics, and biomedicine. Depending on the client's specific requirements, we offer integrated solutions from concept design and formulation optimization to small-scale trials and large-scale production. The following are our main peptide microsphere development services:

We offer peptide microsphere development services based on natural polymer materials (such as gelatin, chitosan, sodium alginate, and hyaluronic acid). These natural materials exhibit excellent biodegradability and biocompatibility, widely used in the medical and cosmetics fields. We can adjust microsphere particle size, surface characteristics, and drug encapsulation rates according to customer requirements, ensuring peptide drug stability and long-term effectiveness.

We have extensive experience in synthetic polymer microspheres such as PLGA, PLA, PCL, and PEGylated materials, providing highly customized microsphere products for our clients. These synthetic polymer microspheres offer excellent drug loading capacity and controllable release characteristics, and their performance can be optimized by adjusting molecular weight, polymerization degree, and other factors.

Lipid microspheres are essential carriers in drug delivery, effectively encapsulating both water-soluble and lipophilic drugs to improve drug stability and bioavailability. We offer customized development for lipid microspheres, including phospholipid microspheres, solid lipid microspheres, and self-assembled liposomes.

Sustained-release microsphere technology can effectively control drug release rates, achieving long-term therapeutic effects. BOC Sciences provides sustained-release microspheres using different materials and processes, ensuring product stability and release efficiency to meet the needs of various drugs and cosmetic ingredients. Our sustained-release microspheres are widely used in long-acting drug therapies, anticancer drugs, vaccine delivery, and other fields.

pH-responsive microspheres can adjust release rates under specific pH conditions, particularly suitable for gastrointestinal drug delivery and local delivery systems. We offer comprehensive development services, from design to production, ensuring that the drug is released at the specific site or environment for optimal therapeutic effects.

Enzyme-degradable microspheres trigger drug release under specific enzyme environments, providing high specificity and controllability. BOC Sciences offers customized microsphere preparation technology, allowing us to adjust enzymatic degradation properties to meet the application needs of various biomedicine fields, especially in cancer treatment and gene drug delivery.

Thermo-sensitive microspheres change their structure or release characteristics at specific temperatures. Our developed thermo-sensitive microspheres respond quickly to body temperature or external temperature stimuli, often used in local drug delivery systems, particularly suitable for therapeutic proteins, peptides, and vaccines.

In addition to the above, BOC Sciences also offers other special functional microsphere development services, including but not limited to multi-responsive microspheres, targeted microspheres, and smart-release microspheres. By combining the latest nanotechnology and material science, we provide forward-looking microsphere solutions to help clients stand out in a competitive market.

BOC Sciences has a comprehensive peptide microsphere preparation technology platform, covering emulsion-solvent evaporation, spray drying, phase separation, self-assembly technology, and microfluidic nanosphering. We can flexibly develop strategies based on peptide properties and product needs. We provide full-process services from peptide screening, formulation design, process development, performance validation to pilot-scale production, helping customers accelerate project progress and reduce development risks.

BOC Sciences has a strong peptide synthesis platform that supports customized design of functional peptides to meet different product requirements for bioactivity, stability, and surface hydrophobicity. We can improve the compatibility and encapsulation efficiency of peptides with microsphere materials through structural optimization and tag modification while providing various forms (powder, freeze-dried, salt forms, etc.) of raw material peptides to ensure smooth implementation of the subsequent microsphere preparation process.

For different application scenarios (such as medical aesthetics injections, cosmetic creams, drug-controlled release formulations), BOC Sciences offers personalized microsphere formulation optimization services, covering carrier material selection (PLGA, PLA, gelatin, chitosan, etc.), peptide concentration control, emulsion system stability design, and more. Our scientific team combines the physicochemical properties of peptides and target release behaviors to design the optimal formulation combination, improving product stability and effectiveness.

BOC Sciences selects the most suitable encapsulation process (such as W/O/W emulsion solvent evaporation, spray drying, or nanoemulsion technology) based on the water solubility, thermal stability, and other properties of peptides. We focus on optimizing process parameters such as stirring speed, solvent ratio, and temperature control to improve encapsulation efficiency, particle size uniformity, and microsphere yield while minimizing peptide degradation and loss of activity.

BOC Sciences utilizes techniques such as adjusting polymer molecular weight, surface modification, and crosslinking density control to design short-term, long-term, or pulsatile release schemes. We provide in vitro release kinetics testing, establish release curve models, and optimize microsphere design based on customer project needs to achieve precise delivery and sustained biological activity, particularly suitable for injectable cosmetic products or controlled-release drug development.

BOC Sciences has a complete peptide microsphere stability research system, conducting accelerated and long-term stability tests under high temperature, high humidity, light exposure, and other conditions to evaluate the physical and chemical stability of products during storage and transportation. We focus on studying peptide activity retention, microsphere structural integrity, and changes in release curves, providing strong support for product filing, registration, and long-term safety.

Successful transition from laboratory development to commercial production depends on process scalability and consistency control. BOC Sciences offers pilot-scale equipment and process development services to help customers achieve stable conversion from gram-level to kilogram-level production.

BOC Sciences has a comprehensive GMP manufacturing system for peptide microspheres, supporting the entire process from gram-level experimental development and pilot-scale validation to kilogram-scale commercial production. We are equipped with advanced microsphere preparation and drying equipment, such as high-pressure homogenizers, spray dryers, microfluidic systems, and more. Our facilities comply with cGMP standards, with capabilities for sterile control, environmental monitoring, and full process traceability. The production process follows QbD and ICH guidelines, covering aspects such as formulation transfer, batch scaling, process validation, clean room classification, and final product release testing. This ensures the quality, safety, and consistency of microsphere products, meeting the stringent requirements for high standards and stable multi-batch supply in the medical aesthetics and pharmaceutical industries.

BOC Sciences has established a systematic and multidimensional quality testing and performance evaluation platform for peptide microspheres. This platform covers critical quality attributes such as physicochemical properties, biological performance, release behavior, and stability, aiming to provide scientific, compliant, and efficient quality control support for clients. Our analytical team possesses extensive microsphere evaluation experience, capable of designing customized testing schemes for different preparation processes and uses, ensuring that products meet industry standards in terms of safety, efficacy, and consistency. Our laboratories are equipped with world-class testing equipment, supporting quality control across pilot to GMP batch products, widely applied in drug registration, cosmetic filing, and preclinical research stages. BOC Sciences is committed to becoming a trusted quality analysis partner for clients, helping products successfully enter the market and advance commercialization.

Peptide microspheres, as an advanced controlled-release delivery system, combine the high biological activity of peptides with the sustained release and targeting properties of microsphere materials. They are widely used in high-value fields such as biomedicine, cosmetics, and medical aesthetics. In medical aesthetics, peptide microspheres enable precise delivery and long-lasting effects; in cosmetics, they enhance the durability of anti-aging and whitening effects; and in biomedicine, they provide ideal carriers for vaccines, anti-cancer drugs, and tissue engineering. BOC Sciences leverages its powerful peptide synthesis platform and microsphere technology to assist customers in developing safer, more stable, and differentiated products, enhancing market competitiveness and accelerating the full-cycle progression of products from R&D to commercialization.

Peptide microspheres are small spherical particles that encapsulate peptides, offering controlled release and enhanced stability. Commonly used in drug delivery and targeted therapy, they improve the bioavailability of peptides. By protecting peptides from degradation, they ensure more effective and sustained therapeutic outcomes in treating various conditions, making them a valuable tool in both medical and research applications.

Peptide microspheres provide prolonged release of peptides, improving their stability and bioavailability. This controlled release mechanism reduces the frequency of administration, leading to better patient compliance. Additionally, peptide microspheres offer targeted delivery, ensuring that therapeutic peptides reach specific sites in the body, maximizing their efficacy while minimizing potential side effects, especially in treatments for chronic or complex diseases.

In biomedical research, peptide microspheres are used for controlled peptide release in drug development, immunology studies, and gene therapy. They help researchers investigate peptide interactions, study delivery systems, and evaluate the potential for therapeutic applications. Their ability to mimic biological environments allows for more accurate in vitro and in vivo studies, improving the understanding of peptide behavior and its therapeutic potential.

Peptide microspheres are created through techniques like spray drying, solvent evaporation, or emulsion methods, which encapsulate peptides within biocompatible polymers. These processes ensure that the peptides are protected from degradation and released slowly over time. The resulting microspheres offer controlled drug release and enhanced peptide stability, making them ideal for medical applications like targeted drug delivery and sustained-release formulations.

Yes, peptide microspheres are made from biocompatible materials such as PLGA (poly(lactic-co-glycolic acid)) and other biodegradable polymers. These materials ensure that the microspheres are safe for use in medical and pharmaceutical applications, minimizing the risk of adverse reactions in the body. The biocompatibility of peptide microspheres makes them suitable for long-term use in drug delivery systems, enhancing therapeutic outcomes while maintaining safety.